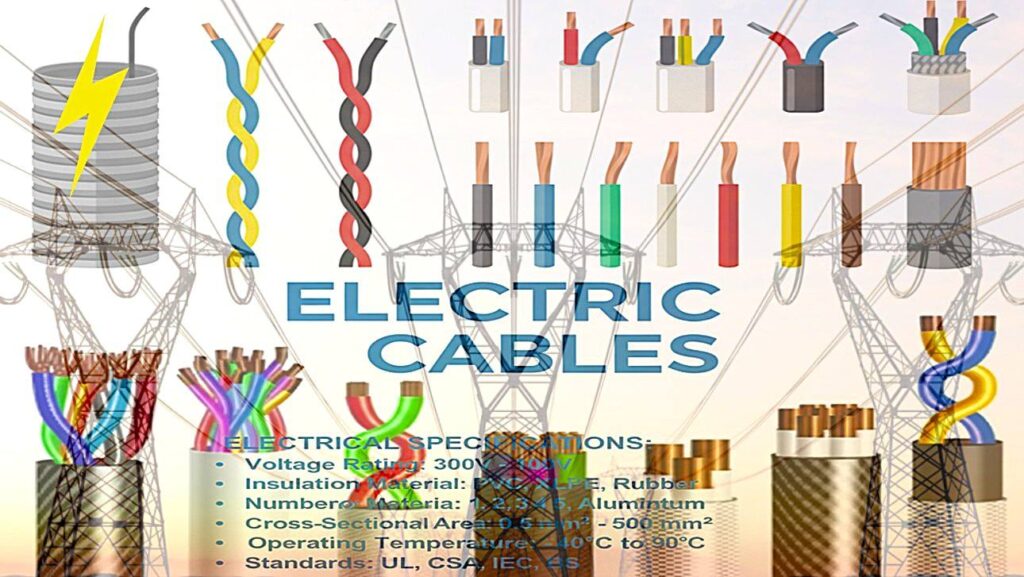

Interactive Electrical Power Cables and Specification

An interactive Tecxskill to explore cable types, understand their specifications of Electrical components, and see how specifications impact performance in industrial parameter .

Cable Explorer

Filter cables by type or feature. Click on the icons Card to follow in details and typical current ranges.

Cable Anatomy: A 2D Technical View

This cross-section illustrates the key layers of a typical power cable, each with a specific function. Understanding these layers is fundamental to cable design and application.

Overall Cable Summary

Component Deep-Tech Spec

Explore core cable components: conductors, insulation, and ampacity factors.

Conductor Materials: Copper vs. Aluminum

Copper (Cu)

- Higher Conductivity: Carries more current for the same size.

- Greater Strength: More resistant to breaking during installation.

- Corrosion Resistance: Less prone to oxidation issues at terminals.

- Cost: Generally more expensive than aluminum.

Aluminum (Al)

- Lighter Weight: About one-third the weight of copper.

- Lower Cost: Significantly more economical, especially for large cables.

- Larger Size Needed: Requires a larger cross-section for the same ampacity.

- Oxidation: Forms an insulating oxide layer, requiring special termination techniques.

Insulation Materials

Insulation prevents current leakage. Its thermal rating limits a cable’s ampacity. The chart shows typical max operating temperatures.

Understanding Ampacity

Ampacity is the maximum current a cable can carry under specific conditions. Use the sliders to see how environmental factors “derate” its base rating.

Effective Ampacity

of Base Rating