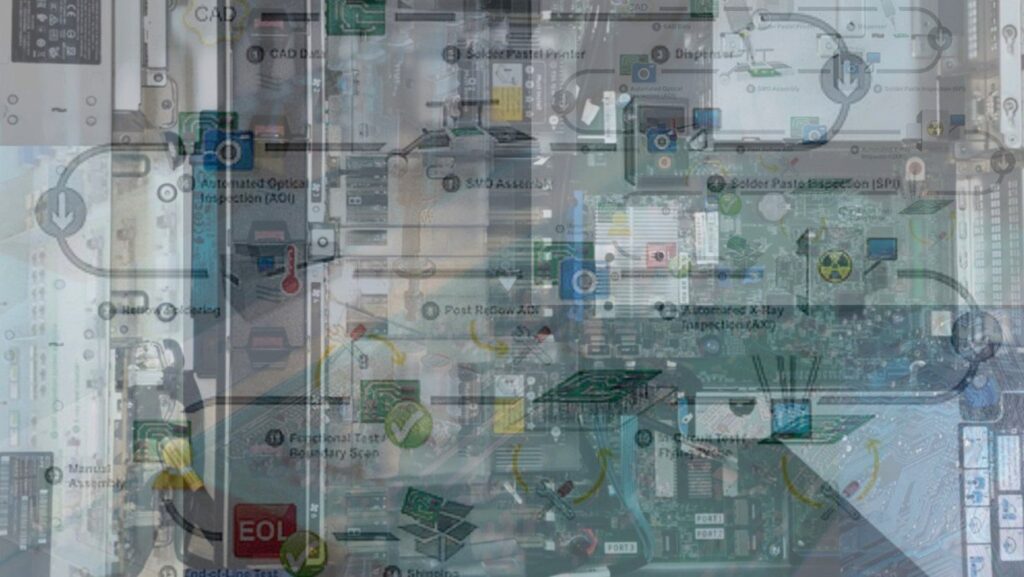

All the necessary electronic components (resistors, capacitors, microchips, etc.) are sourced and assembled. These are then organized into a kit, or “kitted,” for the assembly line to ensure all parts are available with reasonable rate and accounted for before production begins.

Supply Chain & Sourcing Challenges

Component Availability & Lead Times: A critical step is checking the availability ,delivery and lead time of each component with the supplier or vendor. Shortages can cause significant delays in the production schedule. Example: During a global chip shortage, a manufacturer may need to find an alternative supplier or redesign(not good option) their product.

Pricing & Market Fluctuations(traffic ,wars ,disaster ,etc ): The cost of components is subject to change based on market demand ,season and supply. A strategic procurement team constantly monitors price rates to secure the best deals and manage the bill of materials (BOM) cost.

Logistics & Regulatory Challenges: Sourcing from different countries introduces complexities like customs delays, traffic, Wars,trade tariffs, and local regulations. A successful supply chain must navigate these to ensure timely and cost-effective delivery of materials.