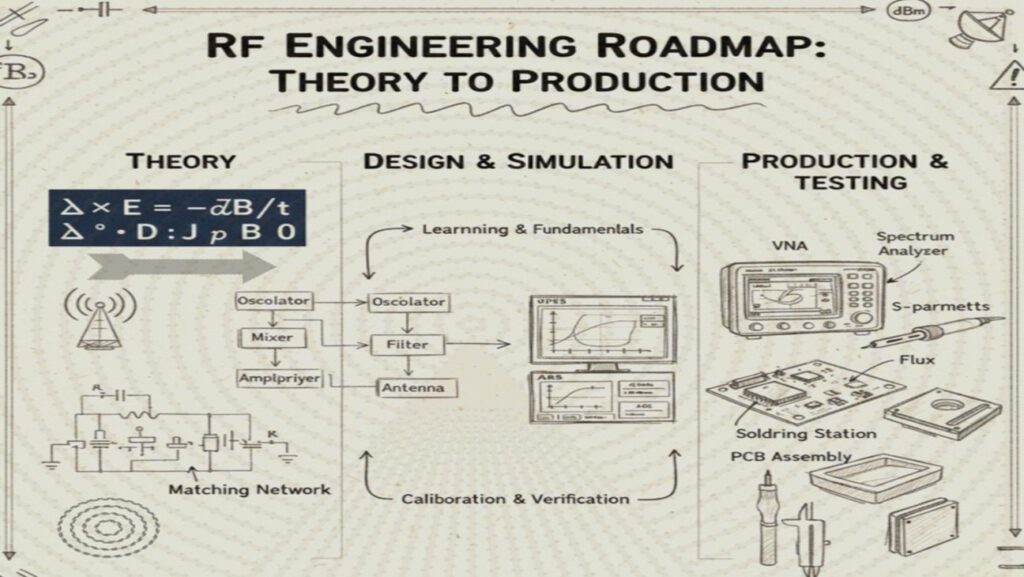

Model of RF Engineering Roadmap

From Fundamentals to Production: A comprehensive journey for the proficient RF Engineer.

🔹 Phase 1: Fundamentals of RF Engineering

The bedrock of all high-frequency design. Without these concepts, simulation and measurement will lack context.

F101 – Fundamentals of RF Circuits

- Physical Principles: Understanding Frequency (f), Wavelength (λ), and Bandwidth (BW). Velocity of propagation in different media (v = c / √εᵣ).

- Impedance Matching: The Smith Chart (admittance/impedance circles), VSWR, Reflection Coefficient (Γ), Return Loss (RL), and Maximum Power Transfer theorem.

- Transmission Lines: Coaxial, Microstrip, Stripline, Coplanar Waveguide (CPW), and Waveguides. Characteristic impedance (Z₀) and propagation constants.

- S-Parameters: Understanding S₁₁ (Input Return Loss), S₂₁ (Gain/Insertion Loss), S₁₂ (Isolation), and S₂₂ (Output Return Loss) in multi-port networks.

F102 – RF Components

- Parasitics: Self-Resonant Frequency (SRF), Equivalent Series Resistance (ESR), and Quality Factor (Q) for resistors, capacitors, and inductors at GHz frequencies.

- Passives: Design and application of Filters (Butterworth, Chebyshev, Elliptic), Bi-directional Couplers, Power Dividers (Wilkinson), Circulators, and Isolators.

- Actives:

- Amplifiers: Low Noise Amplifiers (LNA), Power Amplifiers (PA Classes A, AB, C, D, E, F).

- Frequency Conversion: Mixers (Single/Double Balanced), Local Oscillators (LO), and Frequency Synthesizers (PLL/VCO).

F103 – RF Systems (Analog & Digital)

- Architectures: Superheterodyne, Direct Conversion (Zero-IF), Low-IF, and Software Defined Radio (SDR) front-ends.

- Modulation:

- Analog: AM, FM, PM.

- Digital: BPSK, QPSK, n-QAM, OFDM, and Spread Spectrum (FHSS/DSSS).

- System Budgeting: Calculating Cascaded Noise Figure (NFₜₒₜₐₗ), Cascaded Gain, Linearity (P1dB, IIP3, OIP3), Sensitivity, and Dynamic Range (SFDR).

🔹 Phase 2: RF Simulations

Translating theory into virtual models to predict real-world performance.

S101 – Fundamentals of RF Simulations

- Simulation Types: Circuit (Linear/Non-linear: SPICE, Harmonic Balance, Envelope) and EM (Full-wave: FEM, MoM, FDTD).

- Setup: Defining Boundary conditions (PEC, Radiation/Absorbing), Port types (Wave, Lumped, Internal), and Mesh refinement/convergence.

S102 – RF Structure Simulators (Ansys HFSS / CST Studio / FEKO)

- Antenna Design: Patch antennas, Monopoles, Dipoles, Horns, and Phased Arrays.

- Analysis: Far-field Radiation patterns, Directivity, Gain, Efficiency, Axial Ratio, and Co-polarization vs. Cross-polarization.

- Structure Analysis: Modeling connectors (SMA/SMP), transitions (Microstrip to Waveguide), and cavity resonators.

S103 – RF Circuit/System Simulators (Keysight ADS / AWR / SystemVue)

- Circuit Optimization: Monte Carlo analysis, Yield analysis, and Tuning matching networks/bias tees.

- Non-linear Analysis: Intermodulation Distortion (IMD) products, X-parameters, and Load-Pull simulation for PA design.

- System Validation: Analyzing Link Budgets, Bit Error Rate (BER), Error Vector Magnitude (EVM), and Spectral Mask compliance.

🔹 Phase 3: RF Design Implementation

Moving from idealized simulations to physical hardware constraints.

D101 – Fundamentals of RF PCB Design

- Substrates: Selecting materials (Rogers, Megtron, FR-4), understanding Dissipation Factor (tan δ), and Dielectric Constant (εᵣ) stability.

- Layout Techniques: Controlled impedance traces, ground stitching (vias), microstrip vs. stripline isolation, and minimizing crosstalk.

- Thermal Management: Thermal vias, heat sinks for PAs, and material glass transition temperature (Tᵍ).

D102 – Fundamentals of EMI / EMC & SI/PI

- Integrity: Signal Integrity (reflections, eye diagrams) and Power Integrity (decoupling networks, PDN impedance).

- EMC Design: Faraday cages, shielding cans, Ferrite beads, and differential signaling.

- Compliance Standards: Preparing for Regulatory testing (FCC Part 15, CE RED, ETSI, CISPR).

🔹 Phase 4: RF Measurement and Characterization

Verifying that the hardware matches the design requirements using bench equipment.

M101 – Signal Generators

- CW & Sweep: Producing stable sine waves and frequency sweeps.

- Vector Signal Generators (VSG): Generating complex IQ modulated signals (5G NR, LTE, Wi-Fi 6/7) with fading and AWGN profiles.

M102 – Vector Network Analyzer (VNA)

- Calibration: TRL, SOLT, and Electronic Calibration (ECal) modules.

- Advanced Measurements: Time-domain gating, Group delay, Phase linearity, and Multi-port analysis.

M103 – Spectrum & Signal Analyzer (SA/VSA)

- Frequency Domain: Occupied Bandwidth (OBW), ACPR, SFDR, and Phase Noise (dBc/Hz).

- Vector Analysis: EVM, Constellation diagrams, I/Q Offset, and Symbol timing error.

M104 – Time Domain & Power Meters

- Oscilloscopes: Real-time vs. Sampling scopes for High-speed Jitter and Eye Diagram analysis.

- Power Meters: Peak and Average power sensors for calibrated measurements of high-frequency pulses.

🔹 Phase 5: RF Manufacturing and Production

The final stage: ensuring quality, repeatability, and reliability at scale.

P101 – RF Troubleshooting & Failure Analysis

- Debug: Signal tracing using RF probes, thermal imaging for hotspots, and TDR for cable/trace breaks.

- RCA: Root Cause Analysis of field returns (ESD damage, Dielectric breakdown, cold solder joints).

P102 – Test Fixture & ATE Design

- Mechanical: Pogo-pin fixtures, RF shields, and Repeatability/Reproducibility (Gage R&R) studies.

- De-embedding: Software algorithms to remove the loss and phase shift of the test fixture.

P103 – Automated Testing (ATE) & Quality

- Automation: Controlling instruments via SCPI commands using Python (PyVISA), LabVIEW, or C#.

- Production Metrics: Optimizing Test Time, Statistical Process Control (SPC), Yield Improvement, and Reliability testing (HALT/HASS).

- Expert Oversight: The engineer ensures that production lines maintain high standards of spectral purity and signal integrity through continuous monitoring.

- Process Refinement: One analyzes large-scale data sets to identify manufacturing drift, ensuring that every unit meets stringent performance criteria.

- Strategic Optimization: A specialized lead integrates hardware-in-the-loop (HIL) testing to bridge the gap between initial prototyping and final assembly validation.